Safe Manufacturing-Fish Scale Weld

- Categories:Technical Support

- Author:管理员

- Origin:赛孚机械生产部

- Time of issue:2020-09-07

- Views:

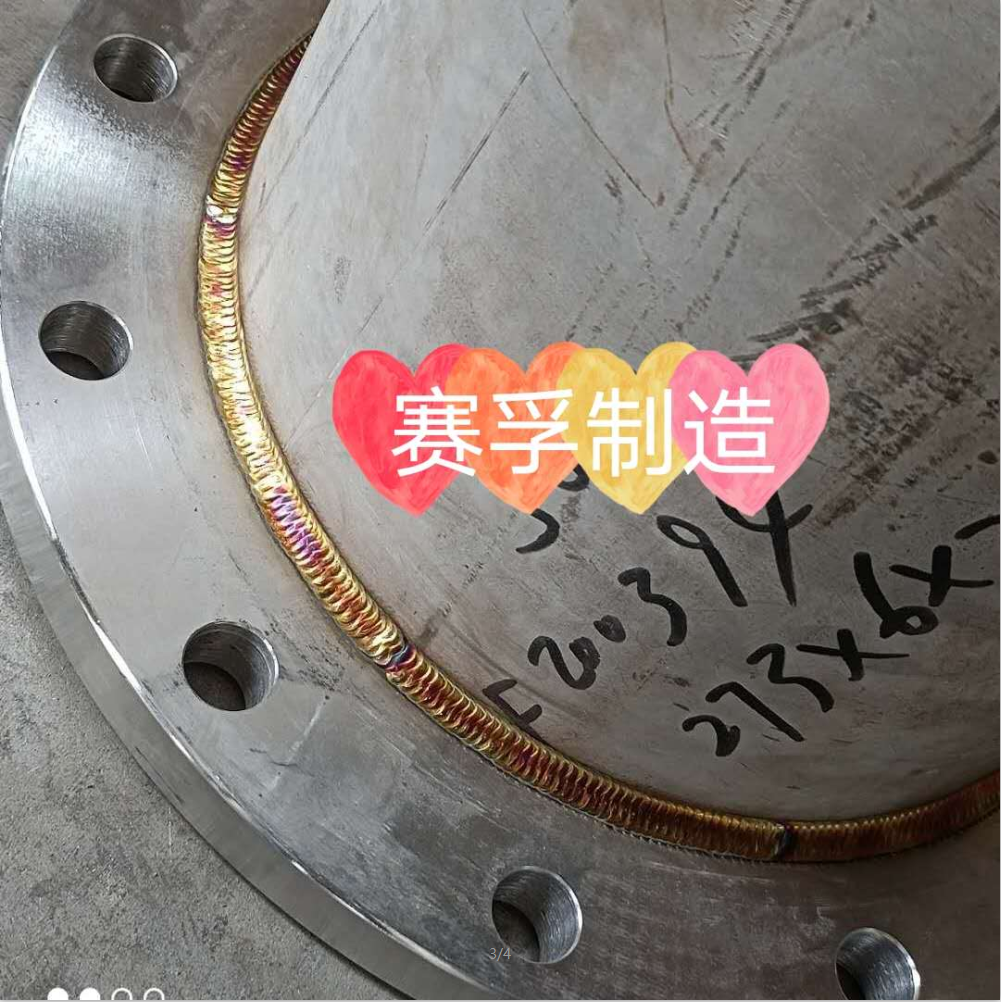

(Summary description)Fish scale welding is a kind of welding level of cattle B. It is named because its welding plane is fish scale. If a welder can get a beautiful fish scale, it is definitely the Rolls Royce and Maserati among welders!

Safe Manufacturing-Fish Scale Weld

(Summary description)Fish scale welding is a kind of welding level of cattle B. It is named because its welding plane is fish scale. If a welder can get a beautiful fish scale, it is definitely the Rolls Royce and Maserati among welders!

- Categories:Technical Support

- Author:管理员

- Origin:赛孚机械生产部

- Time of issue:2020-09-07

- Views:

Fish scale welding is a kind of welding level of cattle B. It is named because its welding plane is fish scale. If a welder can get a beautiful fish scale, it is definitely the Rolls Royce and Maserati among welders!

Fish scale welding is characterized by the direct welding of the pipe to the pipe. Fish scale welding is characterized by the direct welding of the pipe to the pipe.

The main thing is to select the welding point, turn on the power, and strike the arc with the tip of the welding rod to melt the flux in the welding rod, and then swing the welding tongs to the left and right to make the welding core evenly melt at the welding position. Because the general welding effect is good, it will look like fish scales, so it is called fish scale welding! Because the general welding effect is good, it will look like fish scales, so it is called fish scale welding! So it's called fish scale welding! So it's called fish scale welding!

Today, the editor is also fortunate to see the truth of "fish scales" at Safe Machinery's production site——

1. TIG welding itself belongs to the open arc operation, which can observe the shape and flow of the molten pool very well, which is much better than electrode arc welding.

2. Controlling the stability of the hand during welding is the biggest key to avoid trembling and burning of the dock and causing tungsten to be clamped in the molten pool. The control method can adopt the index finger holding the welding torch to support the welded pipe or plate. The extension length of the tungsten electrode can be selected according to the depth of the groove, generally 3~5mm.

3. The wire transport method can be selected according to the size of the groove. When the groove angle is small, the welding wire can be placed in the middle of the bath and fed continuously. When the groove is large, you can use the point feed wire on both sides (to be quite skilled to avoid touching the dock), and the welding torch can be moved left and right to make the edges fused well.

4. Regarding the full scale pattern on the surface, according to the test score standard, the reinforcement of the TIG weld is generally 0~2MM, and the surface is smooth without undercuts, pores, cracks, and no fusion.

How about it, our safe welder is really awesome~!

Scan the QR code to read on your phone

Related News

SAFE Machinery

Condenser, reaction kettle, various towers, evaporator: 86-13773778255

High efficiency heat exchanger: 86-18015913066

Petrochemical complete equipment: 86-15370620536

Tower, reactor, storage tank: 86-13376112662

Northern Region: 86-13584740566

Central China Region: 86-13625232949

E-mail: sfjx@shuangmachem.com

Mobile

Copyright © 2021 Nantong SAFE Machinery Co., Ltd. All Rights Reserved 苏ICP备14056193号

Whatsapp

Whatsapp

E-mail

E-mail Tel

Tel