Grease continuous hydrogenation tower reactor

The hydrogenation of oils or fatty acids has a history of decades in our country, and has achieved rapid development since the reform and opening up. But the oil hydrogenation technology has been lagging behind developed countries for quite some time in the past.

According to the different movement states of the raw oil and fat passing through the reactor, the process of oil hydrogenation is mainly divided into batch hydrogenation and continuous hydrogenation. Since the 1930s, intermittent oil and fat hydrogenation first appeared in Dalian, my country. In the 1960s, Dalian used the medium-pressure tubular reactor continuous oil and fat hydrogenation process for the first time. By the 1990s, my country's oil and fat industry had achieved rapid development, with intermittent hydrogenation. And continuous hydrogenation has been continuously improved and developed, and the process has become increasingly mature. The reaction pressure also transitioned from atmospheric hydrogenation to pressurized hydrogenation and then to medium-pressure hydrogenation. Many oil and fat companies in my country have oil and fat hydrogenation equipment, most of which adopt batch hydrogenation, and a few adopt tubular reactor continuous hydrogenation technology. Although batch hydrogenation has good hydrogenation selectivity and is convenient to start and stop operations, it consumes energy. And the hydrogen consumption is high, the operation is frequent, the safety hazard is large, and the production capacity is low. Continuous hydrogenation is slightly lacking in hydrogenation selectivity, but its production is stable, energy consumption is low, and operation is convenient. It also suffers from low production capacity. Both intermittent hydrogenation and continuous hydrogenation capacity are below 20,000 tons per year per set.

With the gradual entry of foreign capital into the Chinese market, the disadvantages of the low production capacity of the original oil and fat hydrogenation unit have become increasingly prominent, with relatively high production costs, large catalyst consumption, large number of hydrogenation towers, and large fixed investment. Therefore, improving the continuous hydrogenation process to increase the capacity of a single hydrogenation unit, reduce catalyst consumption, and further reduce production costs, became a problem that the domestic oil industry must overcome at that time.

The development of a large-scale continuous hydrogenation tower and the design of related processes were completed in 2006. In 2007, the first domestic 150,000 tons/year oil and fat hydrogenation unit was installed and successfully commissioned in the Rugao Shuangma Chemical Co., Ltd. plant area. The commissioning was completed in 2008. Production runs.

After analyzing the material consumption and products in the process of the installation, the technical and economic indicators of the project have reached the expected purpose of the project after the project was transformed. Specifically:

Extremely hydrogenated oil:

Iodine value ≤0.5mgI2/100g, acid value ≤1mgkoH/100g, melting point ≥58℃.

Partially hydrogenated oil:

Iodine value≤8mgI2/100g, acid value≤3mgkoH/100g.

Catalyst consumption:

Oil weight 0.3‰-0.6‰

Subsequently, the technology and equipment were promoted at home and abroad, and a single set of 200,000 tons/year production equipment was built in Indonesia Dukuda Company (a Chinese-funded company) and was put into production in June 2011. A single set of 150,000 tons/year production unit built in Shandong Jinda Shuangpeng Group Co., Ltd. was put into operation in January 2014.

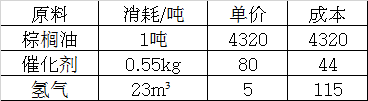

Calculated based on the average price of main raw materials in February 2014, the main raw material consumption is as follows:

Total main raw materials 4479

Including labor, water and electricity consumption and other production costs, it is 114 yuan/ton. According to the product price of 6,200 yuan/ton, the profit and tax can reach 1,607 yuan/ton or more.

The large-scale continuous hydrogenation tower, which is the core equipment of the device, uses multi-layer tube heat exchangers to maximize the amount of heat for the raw material feed (grease) and the continuous hydrogenation tower discharge (extremely hydrogenated oil, spent catalyst, circulating hydrogen) Exchange and recover system energy, only need to provide a small amount of hydrogenation starting energy to ensure the operation of the device and minimize energy consumption.

Related Products

Messages

SAFE Machinery

Condenser, reaction kettle, various towers, evaporator: 86-13773778255

High efficiency heat exchanger: 86-18015913066

Petrochemical complete equipment: 86-15370620536

Tower, reactor, storage tank: 86-13376112662

Northern Region: 86-13584740566

Central China Region: 86-13625232949

E-mail: sfjx@shuangmachem.com

Mobile

Copyright © 2021 Nantong SAFE Machinery Co., Ltd. All Rights Reserved 苏ICP备14056193号

Whatsapp

Whatsapp

E-mail

E-mail Tel

Tel